Our HVAC Conditions Assessment lets you know precisely how your system is impacting your Indoor Air Quality (IAQ) and your bottom line.

An HVAC system can be viewed as a facility’s cardiovascular and respiratory system supplying conditioned air to areas and occupants. The air handler is the heart of this system, where outdoor air is drawn in, filtered, conditioned, and mixed with return air. This “supply” air is then distributed through a network of ducts to and from areas of the building. Primary components include dampers, fans or blowers, heating and cooling coils, air filters, boilers or furnaces, compressors, ductwork to convey the air, and diffusers or registers to distribute the air evenly.

Routine preventive maintenance is the key to avoiding premature wear and tear on components that can lead to repair or early replacement. It is critical to be aware of the system’s condition and components and perform routine cleaning and minor repairs. This proactive approach can extend equipment life and allow for scheduling significant repairs or replacements at a time when it has less impact on disrupting business. Over time, “dirt, dust, debris” can lead to the demise of an HVAC system. At a minimum, unwanted contaminants can inflict damage to equipment that leads to premature wear and tear, increased maintenance costs, increased cleaning costs, and lower operating efficiency.

We offer three distinct AHU assessment services that are designed to help your facility improve your maintenance, indoor air quality and overall system performance:

Level 1 - Visual AHU Assessment

This option provides a site visit where your technician will inspect and assess hygienic conditions within AHUs and ductwork (if accessible, return and supply plenums are inspected).

We then prepare a report outlining physical and environmental condition (visual only), overall condition of AHU of each component part of the air handler; create a proposed plan for remediating deficiencies, if any; specify and order air handler units from most in need of restoration to least in need for facilities planning/capital budget purposes; and provide specific recommendations for rehabilitating/refurbishing the units.

Level 2 - Visual & Environmental HVAC Assessment

This option provides a site visit where your technician will inspect and assess hygienic conditions within AHUs and ductwork (if accessible, return and supply plenums are inspected).

In addition, our technician will collect 3 Surface Tape Preps (STPs) per unit. These samples are sent to a lab for full profile analysis from areas within each AHU, such as the coil, interior cabinet, and blower housing compartment.

We prepare report outlining physical and environmental condition (Visual & Environmental), overall condition of AHU of each component part of the air handler; results of surface samples; create a proposed plan for remediating deficiencies, if any; specify and order air handler units from most in need of restoration to least in need for facilities planning purposes; and provide specific recommendations for rehabilitating/refurbishing the units.

Level 3 - Visual, Environmental & Performance HVAC Assessment

This option includes the scope of work from a Level 2 Assessment, but also includes a full performance evaluation for select units. Performance testing includes the following:

• Measurement of supply airflow by duct traverse.

• Measurement of O/A volume by duct traverse.

• Static Pressure profile of AHU, from Return to Supply Plenum.

• Document the pulley and sheave sizes, center to center distance & RPM of fan.

• Record all motor manufacturer tag data & Actual volts/amps.

• Measurement of Mixed and Supply air temp WB/DB.

• Calculate total MBH.

• Measurement of entering and leaving chilled water temp, if applicable.

• Calculation of actual GPM, if applicable.

We then prepare a report outlining physical and environmental condition (Visual, Environmental & Performance), overall condition of AHU of each component part of the air handler as well as outlined current performance conditions; create a proposed plan for remediating deficiencies, if any; specify and order air handler units from most in need of restoration to least in need for facilities planning purposes; and provide specific recommendations for rehabilitating/refurbishing the units.

Your HVAC system can become dirty over time, which can decrease its performance and degrade your facility’s Indoor Air Quality (IAQ) to the detriment of the occupants’ health.

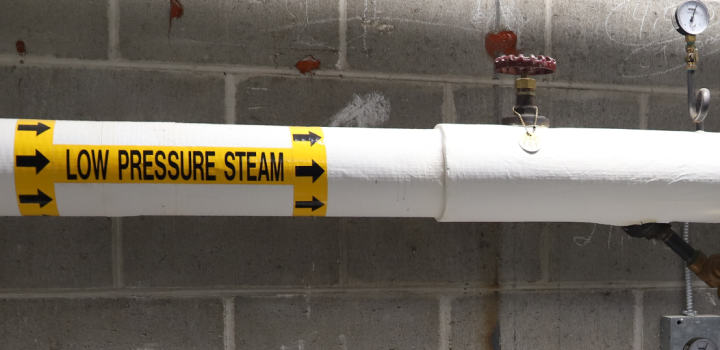

For more information on how our team can help your facility maintain its steam system, please contact us, or visit our clients page to see examples of our work.